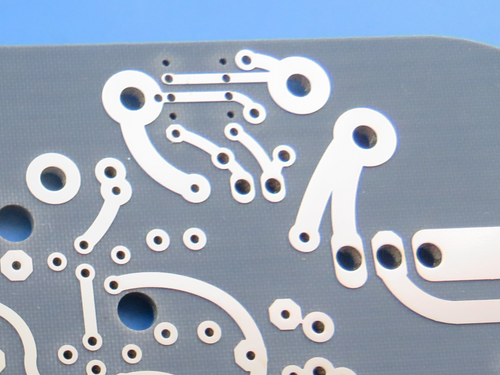

Rogers TMM4 PCB - High-Performance Microwave Material for Advanced Applications

1.Introduction to TMM4

Rogers TMM4 is a thermoset microwave material composed of a ceramic and hydrocarbon polymer composite. This innovative laminate is engineered for high reliability in plated-thru-hole applications, including strip-line and micro-strip designs. TMM4 combines the advantages of traditional PTFE laminates with strong mechanical and chemical properties, eliminating the need for specialized production techniques.

2.Features of TMM4

Dielectric Constant (Dk): 4.50 ± 0.045

Dissipation Factor: 0.0020 at 10GHz

Thermal Coefficient of Dk: 15 ppm/°K

Matched Coefficient of Thermal Expansion:

X: 16 ppm/°K

Y: 16 ppm/°K

Z: 21 ppm/°K

Decomposition Temperature (Td): 425 °C (TGA)

Thermal Conductivity: 0.7 W/mK

Moisture Absorption: 0.07% - 0.18%

Thickness Range: 0.0015 to 0.500 inches (± 0.0015 inches)

3. PCB Construction Details

| Parameter | Details |

|---|---|

| Base Material | TMM4 |

| Layer Count | 2 layers |

| Board Dimensions | 45mm x 54mm (1 PCS, ± 0.15mm) |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | None |

| Finished Board Thickness | 1.3mm |

| Finished Copper Weight | 1oz (1.4 mils) on outer layers |

| Via Plating Thickness | 20 µm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | Blue |

| Bottom Solder Mask | None |

| Electrical Testing | 100% before shipment |

4. PCB Stackup

| Parameter | Details |

|---|---|

| PCB Stackup | 2-layer rigid PCB |

| Copper Layer 1 | 35 μm |

| Rogers TMM4 Core | 1.27 mm (50 mil) |

| Copper Layer 2 | 35 μm |

5.PCB Statistics

Components: 11

Total Pads: 20

Thru Hole Pads: 8

Top SMT Pads: 12

Bottom SMT Pads: 0

Vias: 51

Nets: 2

6.Accepted Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2 compliant

Availability: Worldwide production and shipping

7.Benefits of TMM4

Exceptional mechanical properties that resist creep and cold flow

High resistance to process chemicals, minimizing fabrication damage

Reliable wire-bonding capabilities due to thermoset resin composition

Enhanced reliability of plated-thru holes

Compatibility with all common printed wiring board (PWB) processes

8.Typical Applications

RF and microwave circuitry Power amplifiers and combiners Filters and couplers Satellite communication systems Global Positioning System (GPS) antennas Patch antennas Dielectric polarizers and lenses Chip testers